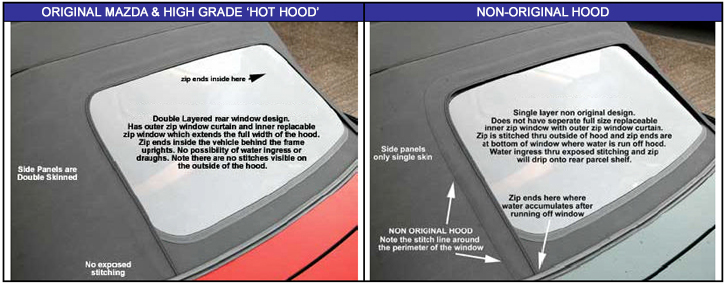

Original

rear zip window design eliminates any possibility of water

leakage through zip.

The hood on the left is a High Grade 'Hot Hood' made to the same design

as the original Mazda hood. The hoods on the right is made

to a non-original design. Look more closely and you will see

that the non-original hood has a stitch line around the zip

window. This is prominent and goes up the sides of the window

and across the top. The original hood has no visible stitching

on the outside of the hood. Stitches that are exposed to the

elements can quickly fade, become brittle and fail. There

are also the obvious problems with water ingress through the

stitch holes. Another major difference is the construction

of the rear section of the hood. The non-original hood in

the photograph has a single skin rear screen design. Compare

this to the original Mazda and High Grade 'Hot Hood' which have a

double skin rear screen window design incorporating a replaceable

inner zip window section which extends across the whole rear

section of the hood and an outer section (or rear window curtain

as it is called) which effectively provides a double skin

layer to the side quarters of the hood. This original design

is more complex. The extra layers of material greatly add

to the insulation properties of the hood and the zip window

positioning provides the best possible protection from draughts

and water leaks.

See the difference between these

two photos.

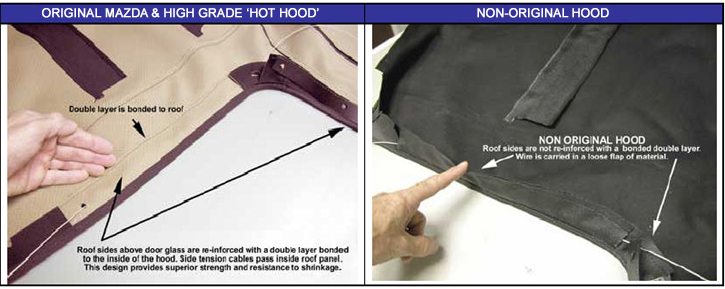

Bonded Double

Faced Edges to Resist Shrinkage

Some hoods are being advertised

with an extended roof area to cover door seals? I find this

claim to be a little misleading. Any new hood that does not

adequately cover above the door seals would be considered

a poor fit and if you extend it beyond the door seals it will

interfere with the door opening. You therefore cannot extend the roof beyond its optimum size but you can ensure it stays that size by using high quality hooding materials and construction methods to re-enforce stressed areas. Mazda and our High Grade 'Hot Hood'

incorporate such features to resist premature shrinkage and

this can be explained in the photos below.

See the difference between these

two photos.

The sides of the original

Mazda & High Grade 'Hot Hood' are double skinned. (See left photo).

This is achieved by gluing a second layer of material around

the inside of the hood. This second layer re-enforces the

sides of the hood and also carries the side tensioning cable.

The side tensioning cable is passed through the material and

held tightly sandwiched within the sides of the hood fabric.

This arrangement not only provides a superior tight seal against

the hood frame but the double layer also provides superior

resistance to shrinkage.

Some after market hoods that

we have seen omit to glue the re-enforcement material to the

inside of the hood. (See right photo). The material is simply

sewn on as a loose flap through which the tension cables will

pass. This loose flap of material is not providing the same

function as the original glued re-enforcements on the original

Mazda and High Grade 'Hot Hood'. The hoods sides remain a single

thickness providing considerable less resistance to shrinkage

and damage. In addition the side cable passes through the

loose flap of material and therefore does not hold the sides

of the hood as well as it was intended too. This non original

design cuts costs from the manufacturing process at the expense

of losing the obvious benefits found in the original design.sts.

We hope that the above information

will enable you to make a more informed choice when choosing

who fits your hood.

|