HOOD INFORMATION

PAGE

Please read the important information below before you make a decision

as to who fits your hood.

|

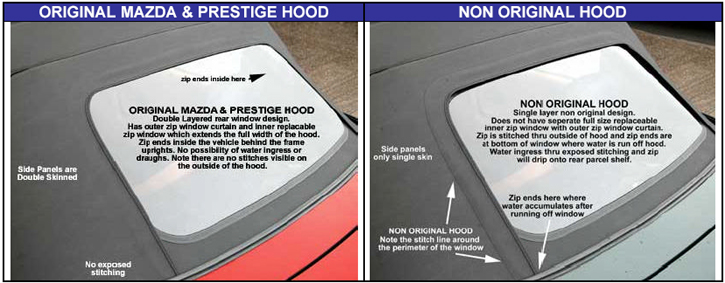

The

hood market is rife with a variety of imitation hoods claiming

to have various design improvements of one form or another.

There are many hoods that are made to non-original design

specifications and there are many inherent problems associated

with some designs. In order to make an informed choice you

need to be aware of many features of the original hood design,

how it is constructed and how to identify those hoods which

do not adhere to the original Mazda design. Below you will

see photographs of both the Prestige Hood which adheres to

the original design and construction methods and photographs

of an imitation hood that is widely available. Sometimes such

hoods are offered with certain claims of new improved design

etc. The photographs below will enable you to identify the

original design |

|

hood against a non original hood. We will point out the various

differences between the two types of hood to enable you to make

a more informed choice when comparing. |

|

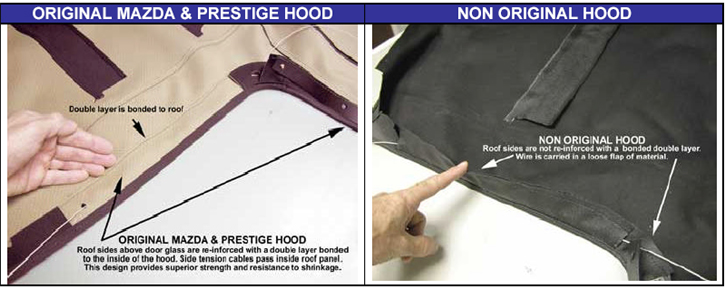

Original

rear zip window design eliminates any possibility of water

leakage through zip. See the difference between these

two photos. Bonded Double

Faced Edges to Resist Shrinkage See the difference between these

two photos. Some after market hoods that we have seen omit to glue the re-enforcement material to the inside of the hood. (See right photo). The material is simply sewn on as a loose flap through which the tension cables will pass. This loose flap of material is not providing the same function as the original glued re-enforcements on the original Mazda and Prestige Hoods. The hoods sides remain a single thickness providing considerable less resistance to shrinkage and damage. In addition the side cable passes through the loose flap of material and therefore does not hold the sides of the hood as well as it was intended too. This non original design cuts costs from the manufacturing process at the expense of losing the obvious benefits found in the original design.sts. We hope that the above information will enable you to make a more informed choice when choosing who fits your hood.

|